Hydrogen pros and cons

2 October 2023

Balfour Beatty has given a further update on its use of hydrogen fuel to power machinery at its Royal Botanic Garden Edinburgh site (above) to lower emissions, with some thought-provoking findings.

In a recent blog post on the company’s website, Group Sustainability Director Jo Gilroy says that the project has previously used an existing electrical connection to power equipment and avoid the need for diesel generators. However, more energy-intensive tasks, such as stripping paint and rust from the cast iron frame of the Victorian Palm House, requires more energy. So relying solely on the existing electrical connection was not feasible, and putting in place another electrical connection would have caused significant local disruption and expense.

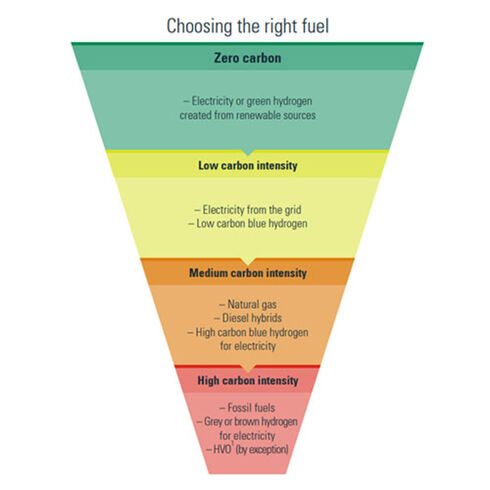

As the power demand would always exceed the capacity of a system using solar power and a battery, Balfour Beatty then turned to hydrogen technology, guided by its Fuel Hierarchy approach (illustrated below) to choosing the next most environmentally friendly option.,

However, the compact nature of the site posed a challenge. As hydrogen is less energy dense than diesel, a typical hydrogen storage unit for construction plant will take up a footprint of approximately 12m by 5m, whereas the same diesel unit would be less than 2m by 2m. This made hydrogen unworkable at this location.

“Transitioning to hydrogen infrastructure is not a like-for-like replacement for existing systems, which means that we will have to make a number of changes in how we approach it, including designing in hydrogen storage areas at bid stage so we are able to set aside the space,” says Jo Gilroy.

She adds that hydrogen does lend itself to other sites, such as the HS2 Balfour Beatty Vinci site near Birmingham where a hydrogen generator is powering a large temporary accommodation building. The company plans to supplement this with a retrofitted solar roof at the same location.

As previously reported Balfour Beatty has received financial support from the Scottish Government to set up a Construction Hydrogen Hub on the M77/Glasgow Southern Orbital project. This involves converting diesel vehicles and construction engines to operate with hydrogen, and is currently replacing 40 per cent of the diesel usage.

The scheme includes two gritter lorries, a traffic management vehicle and an impact protection vehicle. The hydrogen retrofit technology means that the equipment can still run on diesel should there be a fault with the new technology or the hydrogen infrastructure.

Balfour Beatty points out that, while it wants to adopt net zero technology as soon as possible, the lifespan of such vehicles is from 10 to 12 years. Simply discarding them for newer technology is neither sustainable nor possible across its whole fleet.

“Transitioning to hydrogen is a huge task that no individual business can shoulder alone,” says Jo Gilroy. “Our concern is that, without financial support, our sector, and even the broader economy, might struggle to achieve the ambitious decarbonisation goals governments have set.

“For hydrogen to truly succeed, everyone within the hydrogen network must step up – from hydrogen producers to plant manufacturers offering hybrid or fully hydrogen-powered equipment, and every stakeholder in between.

This again shows how the transition to lower-emission technology requires careful management and that traditional energy sources will be in demand for work in many locations for some time yet.